Rear Suspension

One of the early and consistent goals of this project was the use of an IRS. There is a tremendous amount of simply bad and incorrect information written about the benefits and issues surrounding IRS's. So, before I purchased anything, I spent a good bit of time researching the physics and engineering to understand the true issues and solutions. Some issues were as I initially expected but the primary issues were not. Most of my time was spent on the IRS units from the C5/C6 corvette and the 99-04 Mustang Cobra and comparing them to a standard G-Body solid axle.

Before jumping in, it's good to review what a rear suspension is supposed to do:

- Maintain the maximum tire area in contact with the road at all times.

- Must not allow the tires to steer the car (except for rear steer systems)

- Provide suitable ride comfort.

- Minimize the time spent in a dynamic state.

The last point deserves some explanation. The study of most all mechanical engineering systems can be broken down to studies of statics and dynamics. For an automotive suspension, when the spring is a mostly constant length, the suspension can be considered static (technically it must not be changing length at all, but for simplicity, it's easier to allow small motions) . When the spring length is changing appreciably, it is in a dynamic state. A vehicle's suspension spends most of it's time in this mostly static state. During this static state, the tire contact patch should be maximized for that particular condition. When an event occurs (say you hit a bump) the suspension is in a dynamic state as the tire pops around, the springs spring, the shocks absorb and the passengers complain. Eventually this settles down and the suspension returns to a mostly static state. Another example would be braking, the instant you hit the brakes, the car starts decelerating, wheel weight is transferring and the body pitch is changing. Pretty quickly those changes settle out and the car continues to brake in a fairly static state. While the suspension is settling down, it is in a dynamic state. The best performing suspensions minimize the time spent and wheel spends in the dynamic state.

The real advantages of an IRS are:

- Independence. One side can be in a dynamic state while the other side is maintained in a static state. This improved vehicle stability on uneven surfaces. This could be turning, braking or accelerating.

- Lower un-sprung weight. Allows the spring/shock to maintain control of the tire more easily and stabilize a dynamic event.

- Front and rear roll center heights and roll transitions can be closely matched.

- Properly designed IRS systems can eliminate the rear wheel steer present in 4 link solid axle suspensions.

- Aids front to rear weight balance.

Of this list, the first three are the most important. You don't see many solid front axle vehicles for a reason, they really suck to drive. If you hit a pothole on the right, both front tires loose traction. I have owned several solid rear and IRS vehicles, and while the change to IRS is not as pronounced as IFS, it really does make a difference on the street with even moderately spirited driving. The cars are simply more stable in dynamic conditions. A good comparison is the current Mustang and Camaro. If you look at the reviews (or have driven a GT500) the Mustang is the superior vehicle, until you hit a bump in one of the performance versions. The IRS in the Camaro does really shine then (in my opinion, that and the engine are about the only things that do shine)

The real and perceived disadvantages of an IRS are:

- Wheel Hop

- Lack of Anti-Squat

- Heavier

- More Complex and More expensive.

The final two points are accurate in my application. I changed from a 7.5" solid to the Cobra IRS, but I'm not sure that a Ford 9" or GM 12 bolt would weigh all that much less.

The first point is partially correct. An improperly designed IRS is more likely to suffer from damaging driveline vibration issues. Though they are not necessarily wheel hop, they will feel the same from the driver's seat. However, other IRS systems do not show this problem, so the issues are in the implementation of the suspension, not in the basic design.

On a vehicle with a solid rear axle, rotational torque (which is created around BOTH the axle shaft and driveshaft centers) is transferred to the frame at the leaf spring or control arm mounting points. These tend to be relatively long arms mounted out near the wheels. On an IRS vehicle, all of that torque is transferred to the frame through the differential housing. The housing is about the size of a pumpkin, so there are no long arms and the mechanical advantage is miserable. The Cobra differential is located with three rubber bushings. It's pretty easy to see that the differential housing will rotate along both axis as torque is applied. If there is any variability in the applied torque, the differential will start flopping around causing vibration and snapping halfshafts. It's not wheelhop, but does feel like it. The Cobra folks solved the "wheelhop" issue by stiffening the differential mounting points and converting the bushing material form rubber over to Delrin and aluminum.

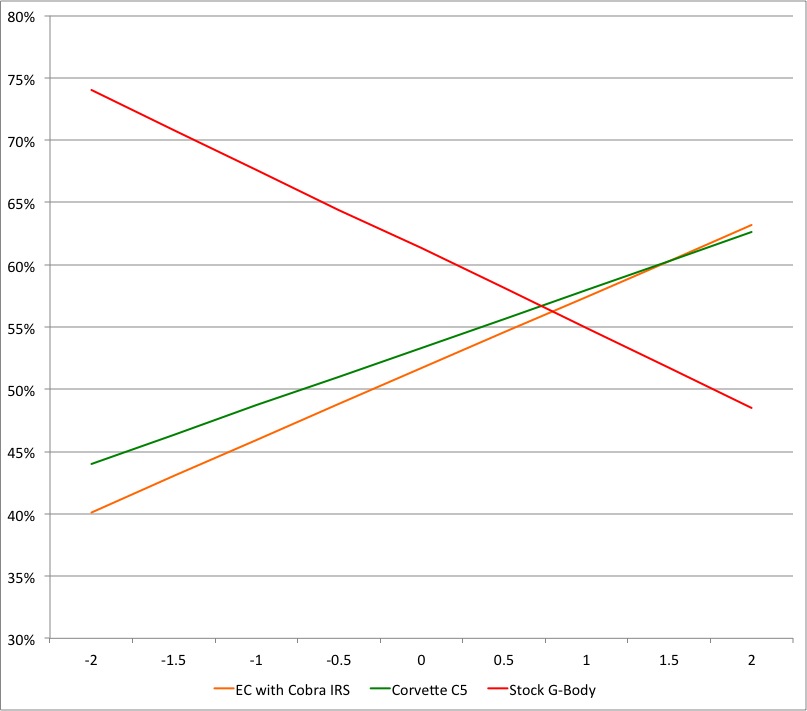

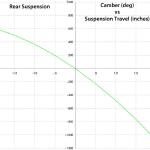

The second point is simply wrong. IRS systems can offer superior anti-squat to solid axles. As an example, below is a graph comparing the anti-squat performance of a G-Body car, a C5 Corvette and my El Camino design. Not only is the amount of Anti-squat similar, the slope of the IRS curves are superior to the solid axle.

Anti-Squat (%) vs Suspension Travel (inches)

Extension

Compression

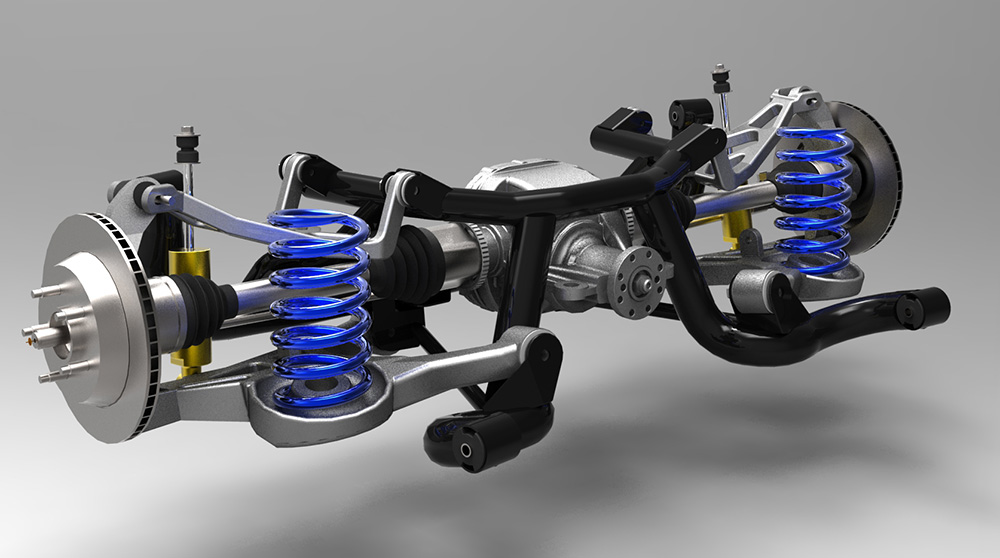

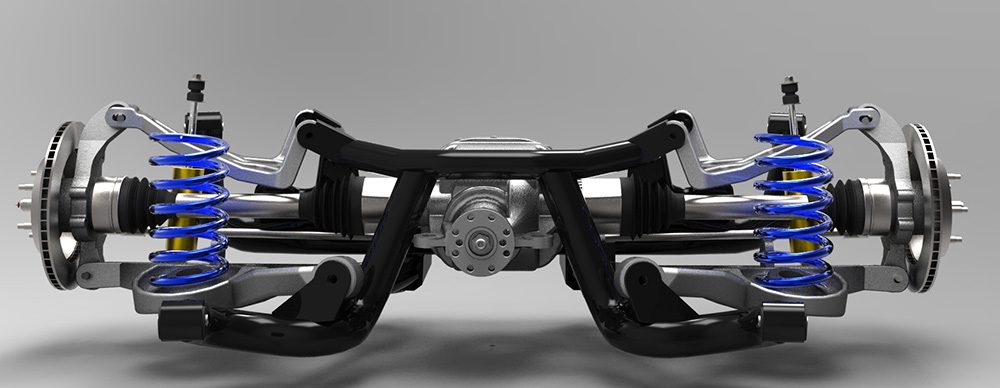

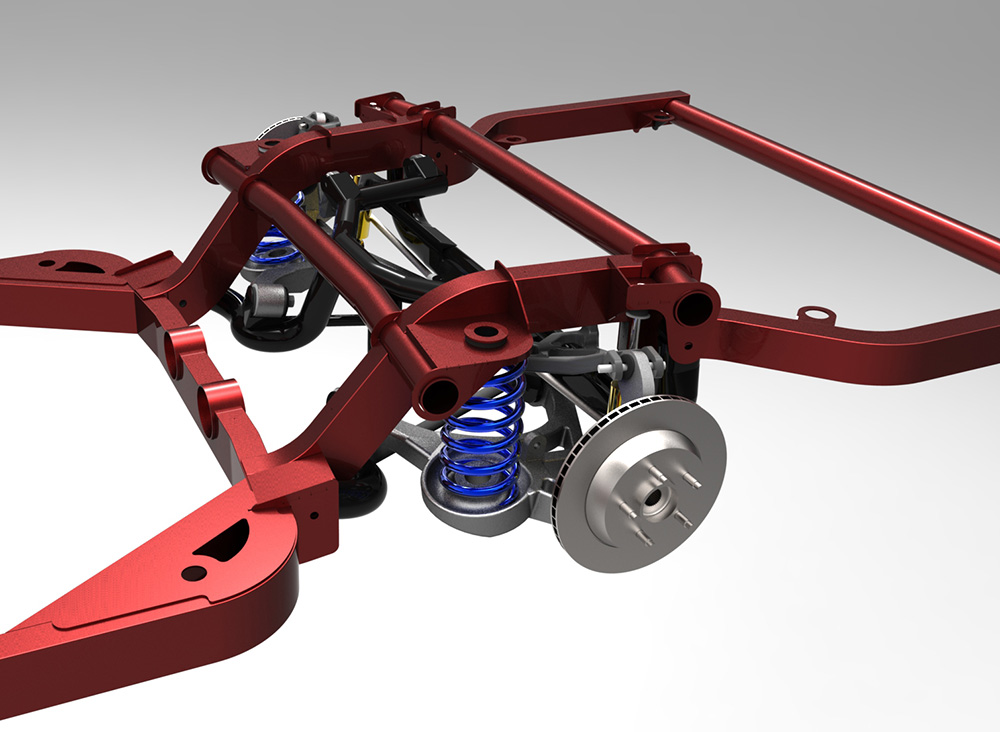

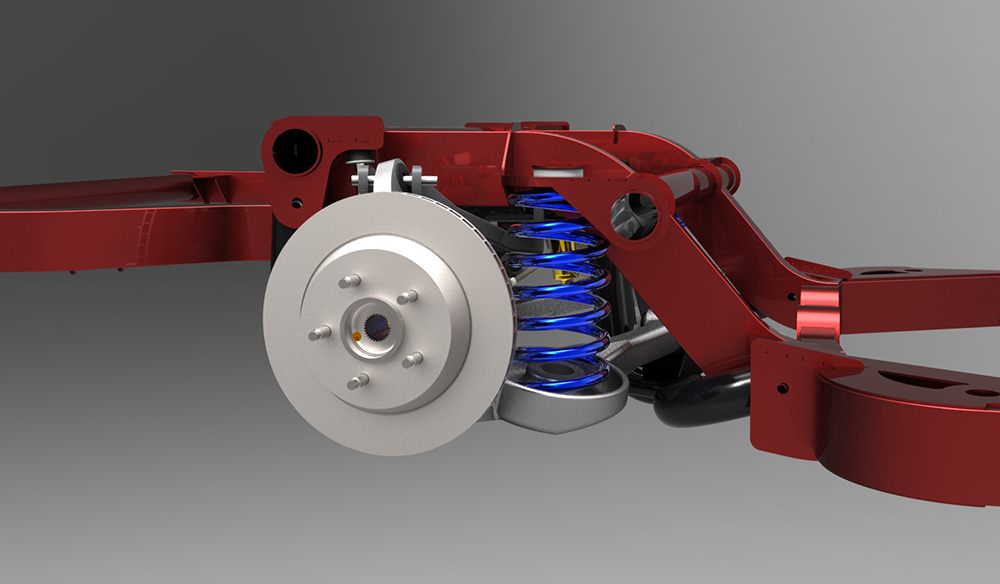

I settled on using the IRS from a 2004 Mustang Cobra. I found one with just under 40K miles which was wrecked in the front and purchased the entire subframe assembly complete with brakes, cables, etc. I believed that purchasing the IRS on a subframe would simplify the task on integrating it into the El Camino. I believe the opposite actually occurred, the subrame really got in the way. But I did manage to locate everything adequately. I apparently deleted the pictures I took of the IRS assembly as it arrived. Below are some rendering of the 3D CAD model I created which provides a reasonable representation of what the IRS Subframe looks like.

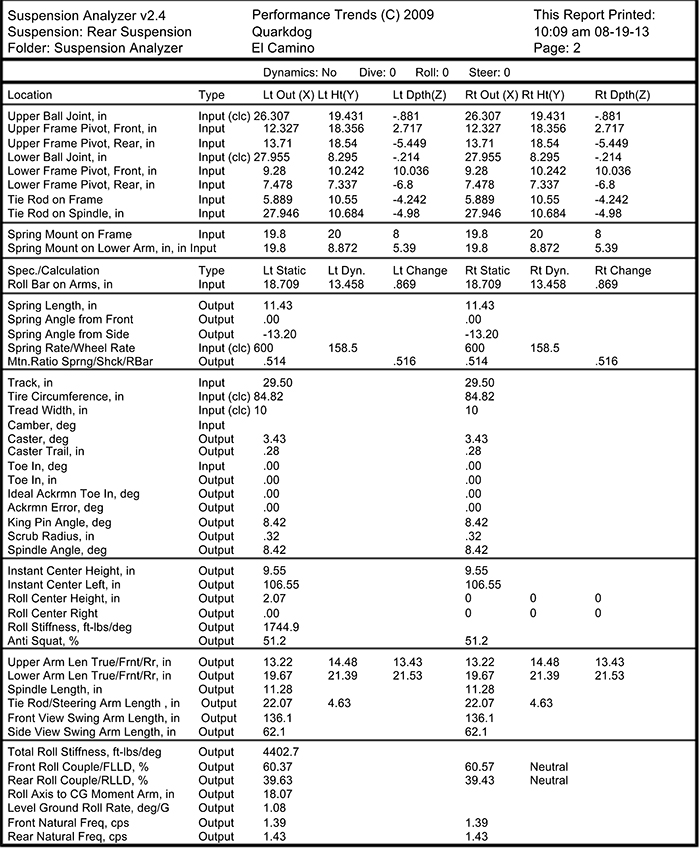

Compared to it's installation in the Mustang, I rotated the front of the subframe up approximately 2 degrees to increase the amount of anti-squat in an attempt to match the C5's specs. All of the suspension mounting points and the resulting performance metrics are shown below:

As you can see from the pictures, routing the frame around the IRS subframe caused the design to be much more complex. Also, the tire width is maxed out at a 285 to clear the rear subframe mount (and the outer fender of the body). If I jettisoned the subframe or used the IRS out of a Mark VIII, I could have easily gone to 315 tires. This Cobra unit cost me $1,300 delivered. If I had gone with a Mark VIII, on the positive side:

- The assemblies are available for about $350 from the local pick and pull yard.

- It's a 4 link design not 5 link, so the mounting would have been easier.

- Larger brakes

However:

- The MarkVIII was not available with limited slip and retrofitting a limited slip differential into a Ford 8.8" housing is apparently troublesome.

- The differential mount would have to be designed from scratch.

- I have no idea where you could buy replacement bushings.

If I did this project over again, I probably would just install a C5/6 IRS and transaxle. In the above section on "wheel hop" I go into more about why, but it would not have been very much more work than what I've put into the Cobra unit.

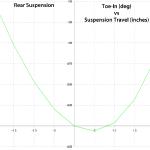

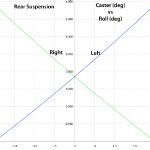

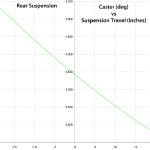

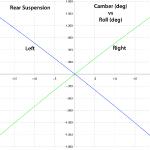

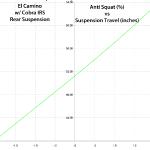

Some of the resulting performance curves are shown below:

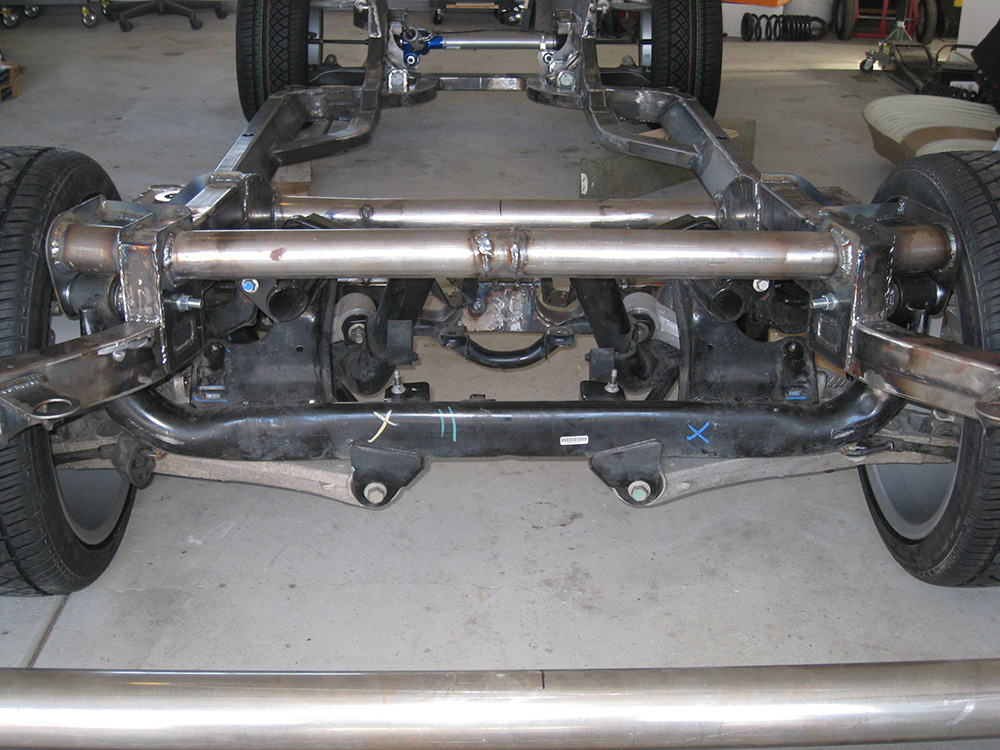

And finally some pictures of the IRS subassembly mounted into the frame:

Below are some 3D renderings of the IRS subassembly mounted into the frame:

Copyright 2014, Leo Stearns